Polylactic acid (H-[OCHCH3CO]n-OH) has good thermal stability, the processing temperature is 170~230℃, and it has good solvent resistance. It can be processed in various ways, such as extrusion, spinning, biaxial stretching , Injection blow molding. In addition to being biodegradable, products made of polylactic acid have good biocompatibility, gloss, transparency, hand feel and heat resistance. The polylactic acid (PLA) developed by Guanghua Weiye also has certain antibacterial and flame retardant properties. And UV resistance, so it has a wide range of uses. It can be used as packaging materials, fibers and nonwovens, etc. It is mainly used in clothing (underwear, outerwear), industry (construction, agriculture, forestry, papermaking), and medical and health fields.

The main advantages of polylactic acid are as follows:

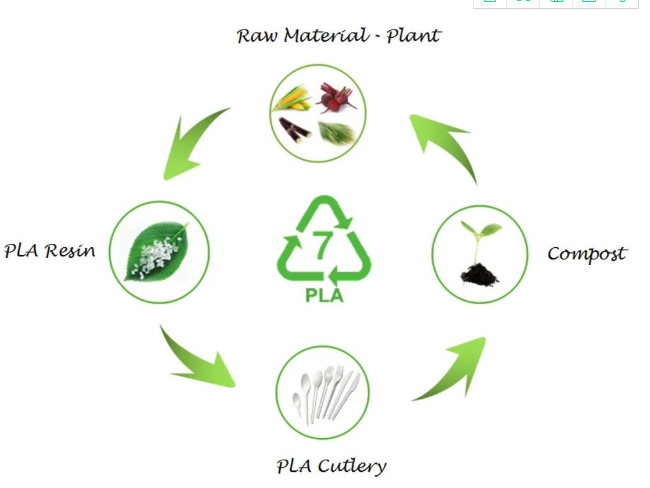

Polylactic acid (PLA) is a new type of biodegradable material, made from the starch raw materials proposed by renewable plant resources (such as corn). Starch raw materials are saccharified to obtain glucose, which is then fermented with glucose and certain strains to produce high-purity lactic acid, and then a certain molecular weight polylactic acid is synthesized by chemical synthesis. It has good biodegradability. After use, it can be completely degraded by microorganisms in nature, and finally carbon dioxide and water are generated without polluting the environment. This is very beneficial to environmental protection and is recognized as an environmentally friendly material. Ordinary plastics are still treated by incineration and cremation, causing a large amount of greenhouse gases to be discharged into the air, while polylactic acid plastics are buried in the soil to degrade, and the carbon dioxide produced directly enters the soil organic matter or is absorbed by plants, and will not be discharged into the air. Will not cause the greenhouse effect.

Post time: Jan-06-2021