LGLPAK.LTD, as an integrated export enterprise integrating the production, processing and export of plastic bags and plastic packaging, has a professional production line. How are plastic bags made? Let's take a comprehensive look at it.

1. Mixing: The raw materials of plastic bags include PE particles, color master particles, and other filling materials. Put it into the container and stir evenly.

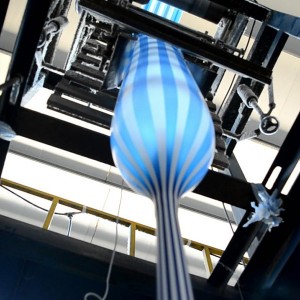

2. Blow molding: the PE raw material is melted by heating, extruded through a circular die head, and the film formed by traction and cooling is called blown film. According to customer requirements, we can produce plastic films with different thicknesses and widths.

3. Printing: generally use offset printing and copperplate printing. Offset printing has fast plate-making time and low plate-making cost, but the printing effect is poor; while copperplate printing uses computer engraving and plate-making, and special treatment such as electroplating on the copper plate is required, so the plate-making time is longer, but the printing effect is better, and Keep this version for a longer period of time.

4. Bag-making/sealing and cutting: Cut and seal the printed semi-finished rolls to make bags one by one; both vest bags and flat-opened hand bags need to use the hot cutting process to directly press the handle.

5. Packaging and delivery: packaging according to customer requirements. Types of outer packaging and packaging methods. The standard packaging of plastic bags is woven bags and cartons. The picture below shows the finished product packed in a carton.

Post time: Sep-30-2020