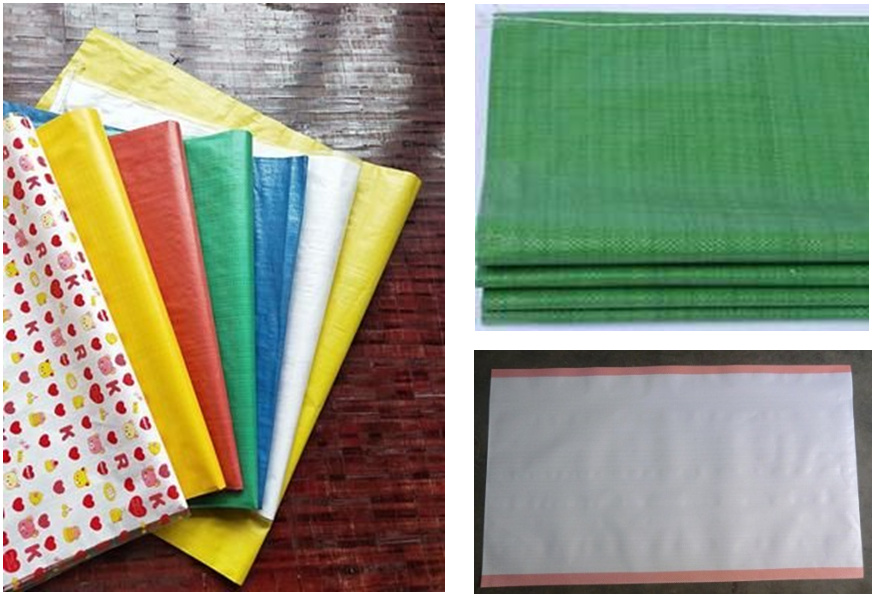

Woven bags, also known as snakeskin bags. It is a kind of plastic bag, used for packaging, and its raw materials are generally various chemical plastic raw materials such as polyethylene and polypropylene. The commonly used woven fabric density is 36×36 pieces/10cm², 40×40 pieces/10cm², 48×48 pieces/10cm². It is made of polypropylene (as the main raw material, extruded and stretched into flat filaments, and then woven, woven, and bag-made. It has a wide range of uses. It is mainly used to make films, containers, pipes, monofilaments, wires and cables, etc. In addition, tents, parasols, various sightseeing bags, sightseeing bags and other daily necessities are used in plastic woven fabrics. In addition, they can also be used as high-frequency insulation materials for TVs, radars, etc.

What are the common parameters of woven bags? Let’s take a look together:

Braid density tolerance: The braid density tolerance refers to the number of flat yarns that are more than the given standard braid density or reduced.

Weight per unit area of woven fabric: The weight per unit area of woven fabric is expressed in grams per square meter, which is an important technical indicator of woven fabric. The square meter weight mainly depends on the warp and weft density and the thickness of the flat yarn. The square meter weight affects the tensile strength and load capacity of the woven fabric. The square meter weight is a major link in the cost control of the production enterprise.

Woven fabric tensile load: tensile load is also called tensile strength, tensile strength. For woven cloth, it bears tensile load in both warp and weft directions, so it is called warp and weft tensile load.

Width: The width of various woven fabrics directly affects the bag-making process. For the tube cloth, the warp is used to indicate the width, and the warp is equal to half of the circumference.

Width shrinkage rate, the width of all woven fabrics after weaving and winding, after unwinding, cutting, printing, and sewing, the width of the bag made is slightly smaller than the width when winding, we call the width shrinkage.

Hand feel: PP flat wire braid has a thicker feel, wider and harder. Adding calcium masterbatch to PP flat yarn will give a wide hand feel. Adding less HDPE to PP will make it softer.

Types of woven bags: Common woven bags are: rice woven bags, flour woven bags, corn woven bags, wheat woven logistics woven bags, flood-proof woven bags, drought-proof woven bags, flood-proof woven bags, and sunscreen carbon black bags, Anti-purple inner line, anti-UV woven bag, etc.

Woven bags are one of the main products of LGLPAK LTD since it engaged in the plastic bag production industry. It has been winning the support and praise of new and old customers with its excellent quality, high production efficiency, breakthrough packaging quantity and professional services, and continuous return orders. .

Buyers from all over the world are welcome to establish close cooperative relations with us. We will provide you with the highest quality products and the most professional services!

Post time: Sep-04-2021